Door Control Unit Obsolescence & Repair

Keeping DCUs in Service

One of TP Matrix’s specialisms is providing obsolescence solutions for train door control units (DCUs). We support fleets across the UK and worldwide.

The DCU is a safety critical system, responsible for driving the door motors, communicating with the train’s vehicle control units and ensuring that the train doors operate safely.

Whilst DCUs’ expected service life is 35 to 40 years, some manufacturers are declaring units obsolete within 10 to 15 years.

TP Matrix’s intervention overcomes obsolescence. After a period of learning on any given DCU, we’ll recommend an interval and overhaul procedure that delivers the following:

Increases DCUs’ reliability and reduces service failures

Enables DCUs to achieve and even exceed their expected service life

Avoids the cost of purchasing a new DCU

Avoids potential further cost and issues of re-designing and modifying train door systems to accommodate the new DCU

Obsolescence Management – TP Matrix’s approach.

1. Condition assessment

TP Matrix’s first step is to perform a condition assessment, which provides the following outcomes:

Observation report – this provides detail about the condition of the unit and includes damage to external casing or framework, heat damage, condition of soldered joints, connectors and sockets condition, condition of all internal components and any other signs of mechanical damage.

Recommendations – listing the materials, components and any other remedial work required due to life expiry or damage.

Additional requirements – lists additional materials needed for the repair, including tooling and test equipment and technical documentation.

Additional requirements – lists additional materials needed for the repair, including tooling and test equipment and technical documentation.

2. Obsolescence assessment

The next stage sees TP Matrix’s sourcing team investigate the long-term availability of all required components.

For any that aren’t readily available, our engineering and sourcing teams work together to source like-for-like alternatives providing the same ‘Form, Fit and Function’. Where necessary, this can involve our own reverse engineering solutions.

Any alternatives are trialled, tested and agreed by the customer before proceeding.

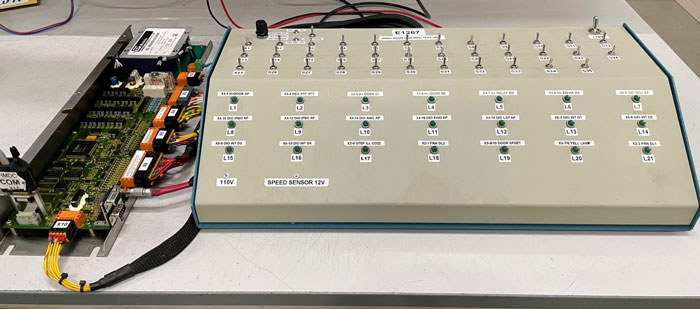

3. Designing and building bespoke testing equipment

At the same time, TP Matrix investigates the most comprehensive testing options for DCUs following repair or overhaul.

Bespoke test boxes allow for quick and reliable testing of all DCU functions and also internal components’ tolerances and communications with other devices.

Both automatic test equipment or manual test equipment solutions can be produced and for some projects we produce both – manual to aide fault finding and automatic for high-volume overhaul. If required, TP Matrix can also document test specifications.

Telephone: +44 (0161) 626 4067

Contact Us Today

We Achieve Success With Our Partners