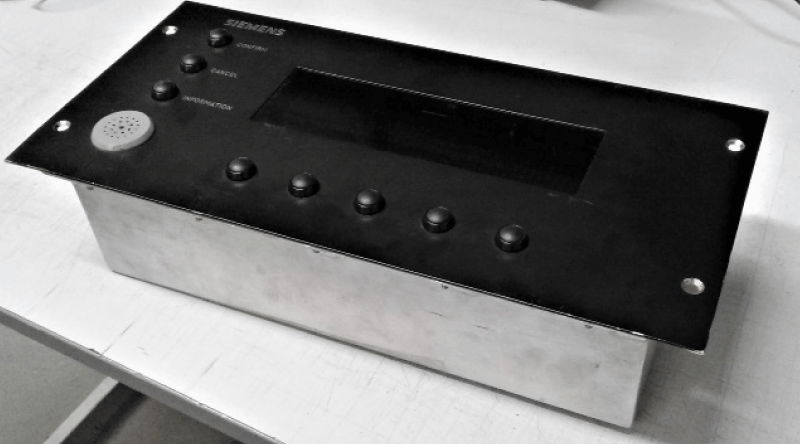

Siemens Class 333 Cab Display Unit (CDU)

Background - Siemens Class 333 Cab Display Unit (CDU)

The Siemens Class 333 fleet are based at the Neville Hill depot in Leeds. The CDU has been declared obsolete by the OEM, furthermore, product support had been withdrawn by the existing supply chain. The depot was now in a critical situation whereby all the float of CDU’s had been declared “unrepairable.” One unit had been in an unrepairable state for 10 years.

TP Matrix were invited to investigate possible solutions.

Our 2 Main Objectives

2 – Assess for obsolete components and provide solutions.

The Solution

TP Matrix performed a Condition Assessment on a sample unit and quickly determined the units were repairable. Two of the faulty units were repaired, tested and installed on vehicles within 4 weeks. TP Matrix engineers were present on site to witness the installation and testing.

During the Condition Assessment it was determined that the main component, a Vacuum Fluorescent Screen was obsolete. Although a later version screen was available, this was not compatible with the CDU.

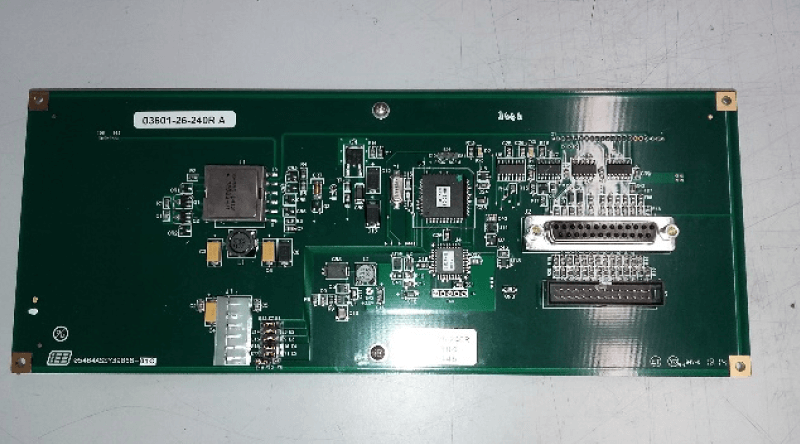

The only viable solution was to design an Interface Card to allow the original control electronics to communicate with the new screen. Siemens provided a design specification and TP Matrix engineers produced the final design and product.

The Process

Designing the Printed Circuit Board based on agreed schematic.

Developing and programming workable codes for microcontrollers based on software specification.

Assembly of interface board with new vacuum fluorescent screen and controller board to supply a complete Prototype CDU.

The Results

Following the completion of design, in-house testing and Type Testing (EMC, Shock & Vibration), the prototype unit was successfully trialled on board a Class 333 vehicle. All faulty float units have been repaired and a robust Test & Repair procedure has been written.

All obsolescence issues have been resolved.

The whole process was completed within 12 weeks.