Resolving Thermal Incidents in Door Control Units (DCUs)

Background

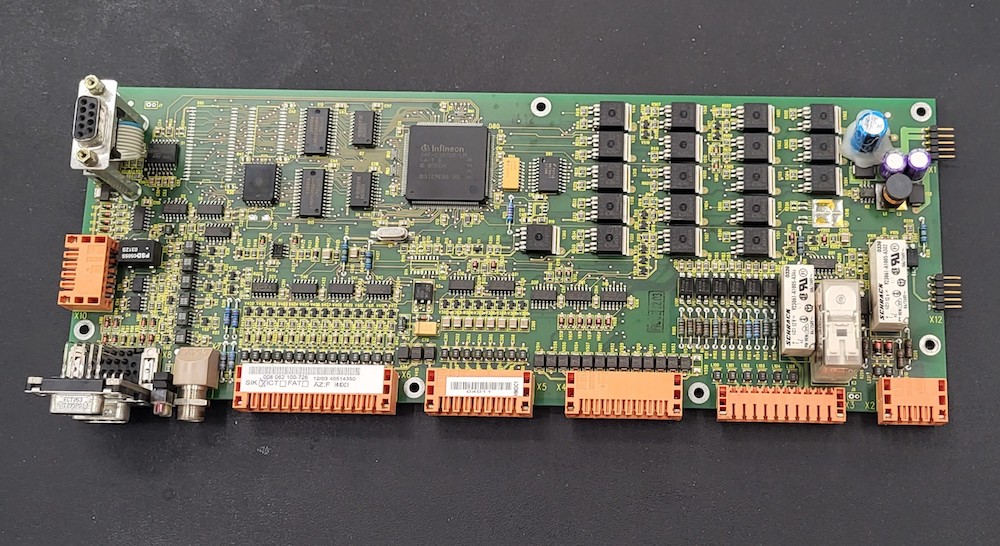

TP Matrix were contracted by a major train manufacturer to investigate and address a series of concerning incidents involving Door Control Units (DCUs) installed in their trains. These DCUs were experiencing numerous thermal incidents during operation that resulted in loss of door operation and the release of smoke into the door vestibule areas.

Additionally, it was discovered that the same faulty components within the DCUs were also creating electrical noise issues which caused communication system disruptions. The railway operator identified these incidents as a critical safety concern and sought a comprehensive solution.

Investigation Process

TP Matrix Ltd initiated a thorough investigation to identify the root causes of the thermal incidents. The investigation spanned several months and involved multiple phases:

Initial Assessment

The TP Matrix team gathered information about the affected trains, the DCUs, and the incidents themselves. They reviewed technical documentation, fault reports, and maintenance records.

Testing

The TP Matrix engineers performed comprehensive testing on sample DCUs. This included analysing power supply unit (PSU) performance, thermal behaviour, and communication stability. They replicated operating conditions to simulate on-board scenarios.

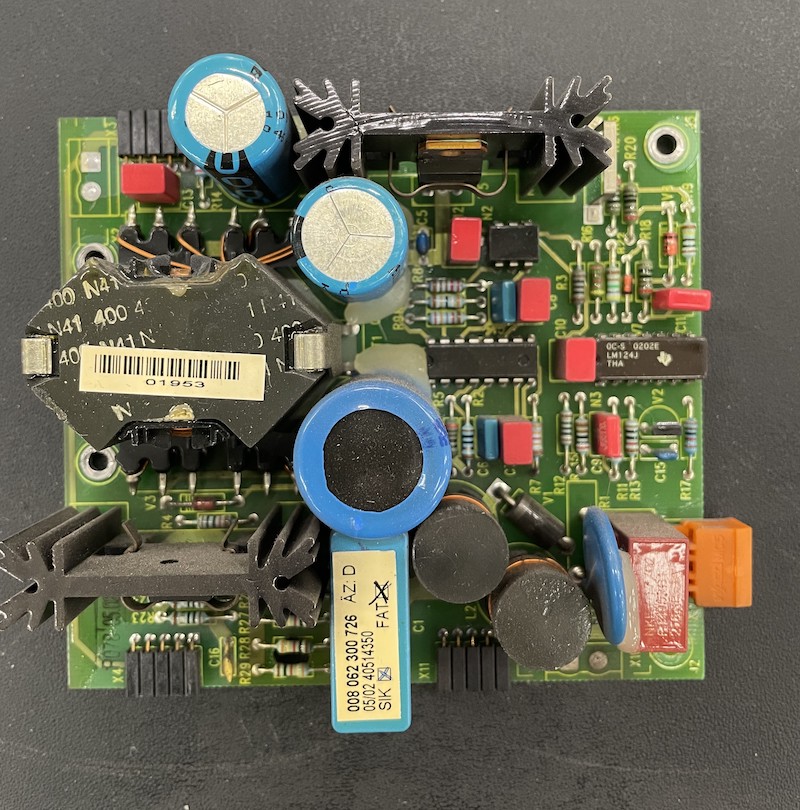

Analysis of PSU

Through extensive testing and analysis, TP Matrix identified that the PSUs of the DCUs were operating below industry standards. These subpar PSUs were causing overheating, which led to the thermal incidents. The inadequate PSU design was also contributing to electrical noise issues and communication system disruptions.

Smoke Incidents

The investigation revealed that the overheating PSUs were releasing smoke in train carriages during some incidents. This posed a significant safety risk to passengers and the overall operation of the railway system.

The Solution

Redesigning the PSU

TP Matrix’s engineering team developed an improved PSU design that met and exceeded industry standards for performance, thermal management, and stability.

Testing and Validation

The redesigned PSU underwent rigorous testing, including EMC, Shock & Vibration testing, to ensure its reliability and safety under various operating conditions. Eight of the new PSUs were fitted to DCUs and were successfully trialled on two fleets in 2018 without any issues.

Rollout Plan

TP Matrix collaborated closely with their customer to establish a phased rollout plan for the new PSU design. So far over 3,000 units have been successfully overhauled to include replacing the PSU along with replacing ageing components in the units (capacitors, relays etc.) to improve the overall performance and reliability of the DCUs.

The Results

The collaboration between TP Matrix Ltd and their customer has yielded impressive results:

Incident Reduction

The new PSU design ended the occurrence of thermal incidents in the DCUs, eliminating overheating-related smoke and noise issues.

Improved Communication

The enhanced PSU design positively impacted the communication systems within the trains, reducing disruptions and ensuring smoother operations.

Passenger Safety

The elimination of smoke incidents improved passenger safety and onboard experience.

Operational Efficiency

With the implementation of the redesigned PSUs, the train operator has experienced fewer service disruptions and improved overall system reliability.

Continuous Improvement

Over the term of the overhaul TP Matrix Ltd have monitored a trend of failures in the communications circuitry. In collaboration with our customer, we offered a solution to this issue which, once approved, reduced the failure rate significantly. This was subsequently incorporated into the overhaul and repair projects. TP Matrix Ltd continuously strives to improve the lifespan of our customers’ products and endeavours to offer continuous improvement to enable this to happen.

Conclusion

TP Matrix’s diligent investigation into the thermal incidents of the Door Control Units showcases our technical expertise and commitment to safety. Through a combination of meticulous analysis, innovative redesign, and strategic implementation, we are successfully resolving the issues, ensuring the continued safe and reliable operation of vehicles for our customer.