Planning for electronic obsolescence management is crucial for the rail industry and is something that should be addressed at the introduction of any new fleet.

Planning for electronic obsolescence management is crucial for the rail industry and is something that should be addressed at the introduction of any new fleet.

Electronic obsolescence refers to the situation where electronic components, systems, or technologies become outdated, unsupported, or no longer available in the market.

This can lead to several challenges if not addressed proactively, particularly in the rail industry where safety, reliability, and long-term operational efficiency are paramount.

Here are the key reasons why planning for electronic obsolescence management is important:

System reliability

Rail systems heavily rely on electronic components for various functions, including control, signalling, communication, and passenger information systems. If these electronic components become obsolete, there is a risk of system failures, breakdowns, and disruptions in operations. Planning for obsolescence management ensures that critical electronic components are identified, monitored, and replaced or upgraded before they become obsolete, ensuring system reliability, and minimising the risk of unexpected failures.

Safety and compliance

Safety is of utmost importance in the rail industry. Obsolete electronic components may not comply with the latest safety standards or may lack the necessary support for security patches and updates. By planning for obsolescence management, rail operators can ensure that safety-critical systems remain up-to-date and compliant with regulatory requirements. This helps maintain a safe operating environment for passengers, staff, and the surrounding communities.

Safety is of utmost importance in the rail industry. Obsolete electronic components may not comply with the latest safety standards or may lack the necessary support for security patches and updates. By planning for obsolescence management, rail operators can ensure that safety-critical systems remain up-to-date and compliant with regulatory requirements. This helps maintain a safe operating environment for passengers, staff, and the surrounding communities.

Cost efficiency

Obsolescence management involves predicting and managing the lifecycle of electronic components. By proactively identifying and addressing obsolescence risks, rail operators can avoid costly emergency repairs, workarounds, or complete system replacements. They can plan and budget for component replacements or upgrades in a controlled manner, optimising maintenance schedules and minimising unexpected expenses. Effective obsolescence management also allows operators to take advantage of advancements in technology, leading to improved efficiency and reduced operational costs in the long run.

Long-term asset management

Rail fleets have long operational lifecycles that can span several decades. Effective obsolescence management ensures that electronic systems and components are adequately maintained and upgraded over time. By planning for the management of electronic obsolescence from the outset, rail operators can optimise the lifecycle of their assets, maximise return on investment, and extend the operational lifespan of their fleets.

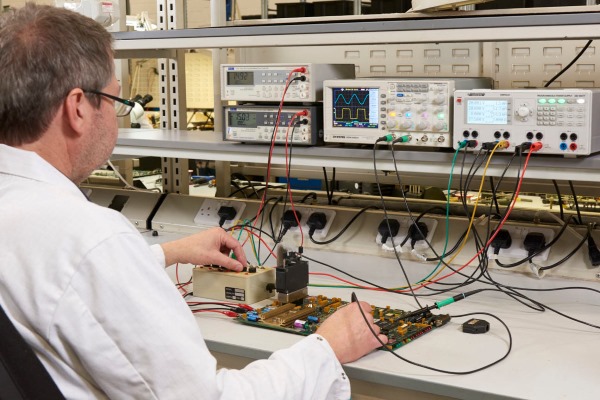

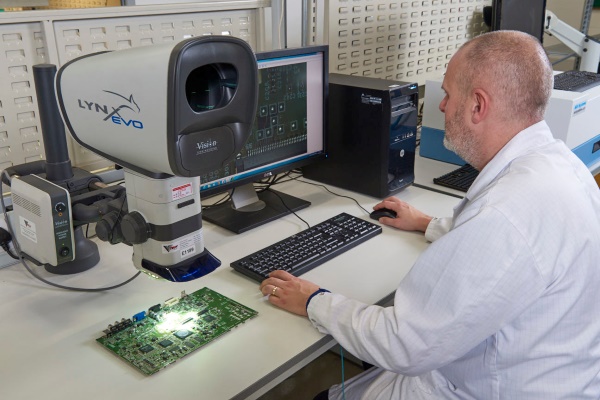

TP Matrix Ltd offers obsolescence management services to help our customers mitigate operational disruptions, enhance safety, reduce costs, and optimise the performance and longevity of their fleets. We achieve this through obsolescence monitoring, component identification, lifecycle planning, supply chain management, and last-time buy strategies.

Get in touch today for more information on our services – michelle.greenan@tpmatrix.co.uk